Our production means

Our core business is in small and medium production runs, but our modern, high-performance means of production enable us to handle larger-scale production runs.

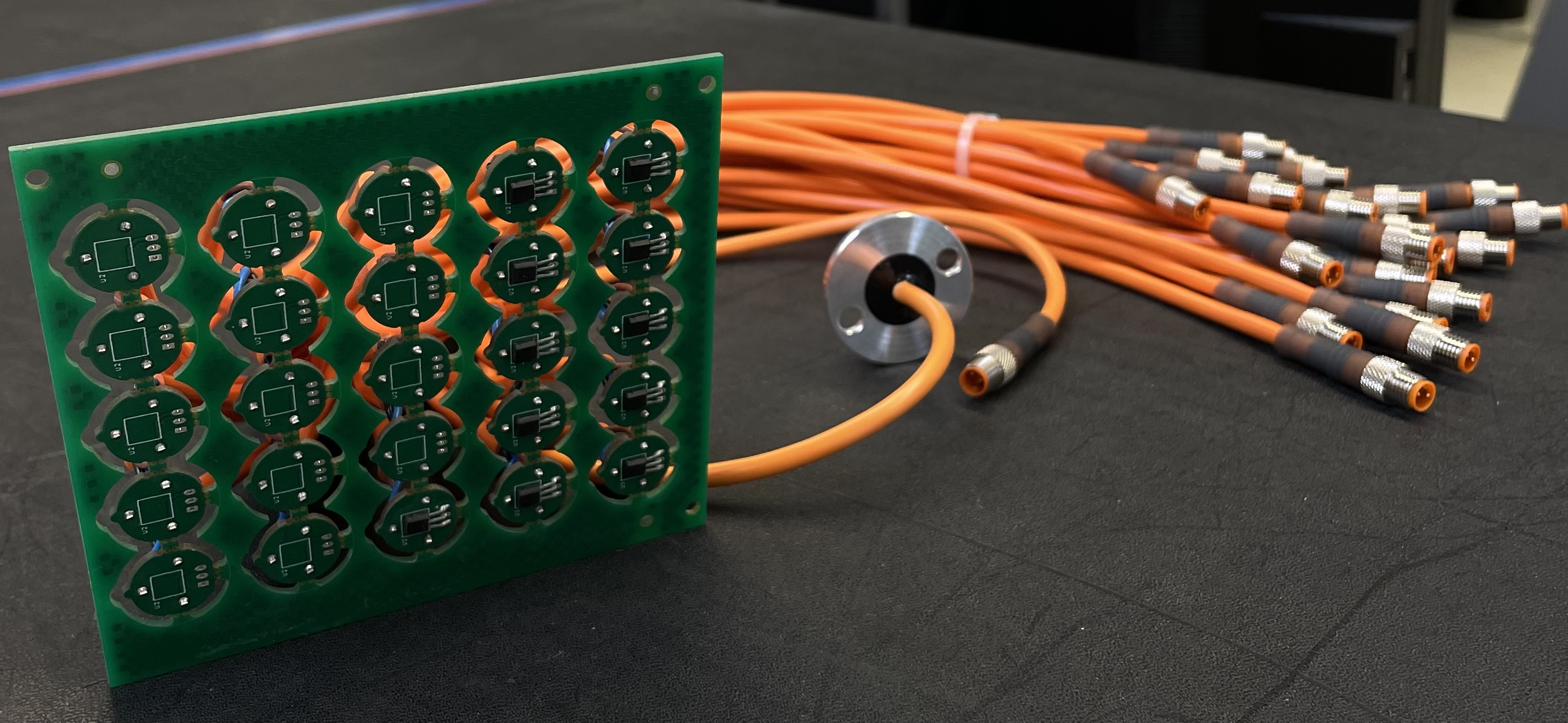

Electronic boards

In addition to a mastered manufacturing process adapted to both recent and older technologies, we offer a wide range of services associated with electronic board assembly.Boards can be assembled according to a RoHS or SnPb process, depending on customer requirements.

Other specific documentation requirements can be handled on request (IPA report, DVI,FMECA analysis, etc.). Complete manufacturing files are archived and can be consulted onsite.

Key strenghts

A flexible production tool (ability to switch from one production run to another quickly), staff trained in IPC A 610 class 3, IPC-7711 & 7721 repair, implementation of a manufacturing process adapted to the specific features of each board (use of Mycam software for manufacturing drawings).

Technologies mastered

BGA and QFN, direct Fet, SMD components, SMD installation, SMD small packages up to01005, through-hole components, high-density boards, rigid flex boards, wire bonding.

Related services

Spray varnishing (acrylic and silicone varnish), potting, gluing, mechanical assembly.

Testing and reliability

AOI inspection (systematic), 100% visual inspection (systematic), burn-in, mobile probe test, AOI inspection (systematic), functional test.

Prototyping

Since the end of 2023, as part of its strategy of supporting its customers and prospects, and with the support of its Lean Manufacturing approach, Seprolec has set up a complete process for prototyping requirements. In addition to board assembly, our aim is to support our customers in the industrialization of their products, right from the prototyping phase. Our services can therefore be accompanied by a DFx package (Design for Test - Assembly -Procurement - Cost, Automatic assembly...), through which our customers can control their design.

Traceability

- Tracking sheet

- Declaration of conformity

- Tracking & tracing sheet

- Test report

Automated assembly line

- Screen printing machine

- Reflow open

- Automatic SMD/BGA layout machine

- Automatic inspection (AOI)

Finishing & retouching room

- Equipped individual workstations

- BGA inspection station

- BGA rework station

- Press-fit insertion station

- Spray varnishing unit

Test & reliability island

- Mobile probe tester

- Climatic chamber (burn-in)

- Functional test equipment

- VRT chamber

A robotized varnishing line

- Acrylic varnish

- Product burn-in facilities available to suit customer requirements (standard & moist heat)

- Card washing machine

Two selective wave systems

- Selective waves: one single pot and one double pot

- Two traditional waves: RoHs & SnPb

Wired cabling

We have recently made a number of investments in this field, enabling us to present a technically comprehensive and competitive offering.

Other specific documentary requirements can be handled on request (IPA report, DVI,FMECA analysis, etc.). Complete manufacturing files are archived and can be consulted onsite.

Key strenghts

High-performance production facilities

Staff trained to IPC A 620 class 3

Implementation of a manufacturing process adapted to the specificities of each wiring (use of Mycam software for manufacturing drawings).

Typology of products manufactured

Bundles, strands, harnesses, cabinets, boxes, desks, test cases

Testing & reliability

Continuity check (systematic)

100% visual inspection (systematic)

Continuity and insulation check (automatic wiring tester)

Dielectric test

Contact pull-out test (on all on-board products or on request)

Mastered technologies

Use of heat-shrink molded parts, coaxial cable, crimping and soldering qualified as special processes, several shielding recovery techniques are mastered and chosen in agreement with our customers according to cable specifications, potting, etc.

Traceability

To ensure complete traceability and transparency, the following documents are supplied with the boards: tracking sheet, declaration of conformity, service and traceability sheet, test report.

Automated assembly lines

- Equipped individual workstations

- Automatic cutting and stripping machine

- Rotary stripping machine

- Crimping press

- Coaxial stripping machine

- Crimping pliers and tooling pool

- Crimp test bench

- Sefelec Synor tester (continuity and isol

- Dielectrimeter

Other resources

CMS

210 000 components per hour

4 complete, self-contained SMD lines, with plans for 6 in the future at Seprolec, and 1 similarSMD line at Aria.

Capable of fitting 01005 and 0.3mm pitch.

Screen printing machines

Latest-generation application machines (integrated electrical testing and traceability)

Reflow ovens (inerted)

Optical (AOI 3D) and X-ray inspection

SPI 3D control of solder cream deposit

Information systems

Card unit traceability

Production managed entirely by ERP. MES (Manufacturing Execution System) managing unit traceability and real-time production planning/monitoring.

Mobile probe testing, functions and programming

Takaya & ICT tester. Over 100 functional test benches (analog, digital, power, RF, GPS...), some of which are produced in-house. On-site or stand-alone programming. Climatic resources (ovens and VRT)

Integration and testing

Over 80 workstations on a 2,000m2 site, dedicated to integration. Organization into lines dedicated to finished or semi-finished products: assembly (mounting, wiring), testing, configuration, packaging. Facilities and space dedicated to endurance testing (HALT). Static or dynamic burn-in with measurements.

We can propose temperature cycles or use those requested by our customers. Mobile probe testing, with coverage rate supplied. Functional testing: we have a laboratory equipped with the main equipment required, and we also use customer-supplied benches. In-situ or pre-wiring component programming. Adjustment of equipment or boards.

Component storage

Isolated storage in controlled environment. MSL storage cabinets for humidity-sensitive components.

Specific products

We have developed a range of probes to measure force, shock and the speed of sound in materials:

"All-or-nothing" probes

Electromotive force probes

Ionization probes

Warehouse

25 000 component part numbers

Over 25,000 part numbers managed. Computerized component traceability. Humidity-sensitive components stored in dry cabinets (in compliance with JEDEC). Dry-pack machine.

Preparation

Components: preforming machines (cutting, bending...). Wire: cutting, stripping and crimping machines. Assembly: different types of presses (mechanical crimping, press-fit, etc.).

Board workshop

Inspection, insertion and finishing

Over 50 workstations dedicated to the various stages of production. 2 EPM waves (inerted)dedicated to RoHS and lead processes. Selective wave. Board washing machine with ionic contamination measurement. Dedicated repair stations, equipped for BGA and LGA disassembly/reassembly. Re-beading equipment. Acrylic and silicone tropicalization according to IPC: spray varnishing, robot varnishing in an air-conditioned area, varnish thickness control, UV control stations.

Supply management

Our purchasing department is made up of 14 people, divided between Seprolec and Aria.

Overall purchasing volume exceeds €40 million.

Suppliers

We have a panel of suppliers who are monitored and audited for different types of services and parts, in particular: mechanical parts, printed circuits and windings.

Stocks

We manage over 20,000 component references in stock, enabling us to guarantee rapid production launches.

We set up dedicated inventories (IT and physical) that can be financed by our customers or in partnership, enabling optimal management of large-scale projects.

Technical skills

Our technical skills enable us to manage obsolescence problems in the best possible way: proposing equivalents, sourcing, etc.

Discover all our markets and applications

Transportation

(urban, rail, aeronautics, naval)

Defense

& security

Embedded systems

Telematics,

M2M & IoT

Measurement

& Analysis

Power electronics

Telecom &

Microwave

Broadcast

& Multimedia

Industry

Geolocation

Medical

Defense

& security

Electric accumulators

Civil & military nuclear

Ground and airborne aeronautics

Video processing & compression

Broadcast

& Multimedia

Agricultural sector

Space

Geolocation

Industry

Metrology

Lab - Medical

Want to chat?

An electronic project? A simple question?

Don't hesitate to contact us to discuss it together!